What Hydro Dipping Kits Do I Need For Water Transfer Printing?

Before you hydro dipping, you might want to know what hydro dipping kits you need for this process. This article will cover the materials used in a hydro dipping kit, how it’s applied, and how to choose them. Having an idea of how much a hydro dipping kit will cost can help you decide whether the process is right for you. After reading this article, you will have the confidence to purchase a hydro dipping kit.

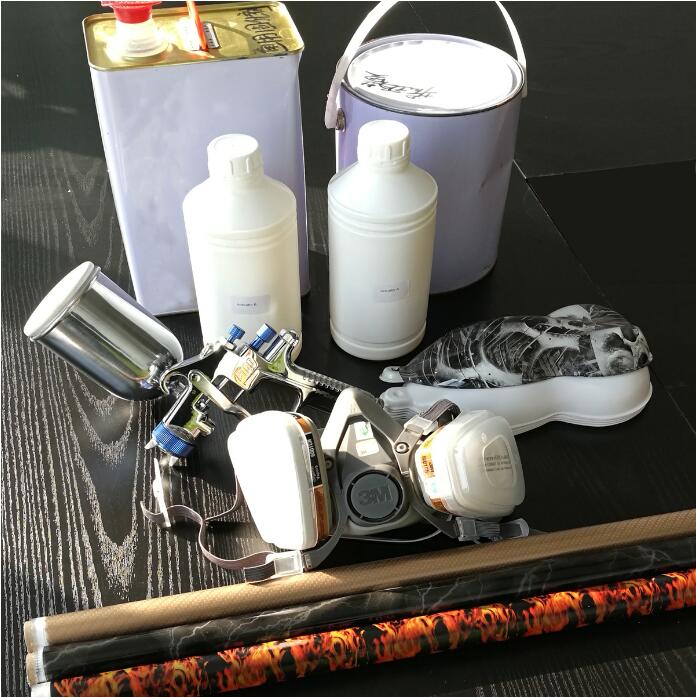

Hydro dipping kit for water transfer printing

Hydro dipping process

To start off, you will need to prime the object, which helps the film adhere to the surface. This process can take anywhere from one to two hours.

The basic hydrographic process is fairly simple to perform. The process of applying a hydro dip film sheet is essentially the same as applying a regular paint or ink-based product. The water-based base dissolves the solution over the printed film. The sprayed object is then immersed into the water and the ink bonds to the surface of the item. Once dipped, the item must be cleaned and primed.

The detailed process, you can turn to blog: Fully Introduction of hydro dipping or How to hydro dipping speedshape at home?

In a summary:

A hydro dipping kit includes everything you need to create a high-quality hydrographic print. The kit contains everything you need to get started, including the object you will dip, two buckets, a mask to block hydro dipping smell, a spray gun, an activator, primer and rubber gloves.

Things you need to care for in the hydro dipping process

Certain Dipped Material

The first step in making your own custom decorations with a hydro dipping kit is to determine what types of materials you want to use. Hydro dipping can be used on a variety of materials, from ordinary light bulbs and pipes to automobile parts and garage equipment. For the best results, you should choose a material that is hydrophilic or will absorb water. Different materials may require different types of paint or base coats, so make sure to purchase the right one for your project.

The most popular material used for hydro dipping is plastic or glass. Plastic or glass materials work best, but other materials may work just as well. If the material is not water-resistant, it may warp and not turn out as well. A hydro dipping kit will contain the proper materials for transferring your designs. If you want a certain design, you can contact the manufacturer and ask for examples. There is no need to purchase a hydro-dipping kit if you do not intend to use it.

Glass is almost no more different in the selection of based costing, but the plastic has many types such as PP, PE, and PVC, it is very important to certain the material, which determines the base coating type.