What equipment do you need for hydro dipping?

1.Spray gun and a compressor

Everyone who works on hydro dipping will know that spray gun and a compressor is important hydro dipping kit during the water transfer printing process.

You need to pour off the liquid activator into the spray gun bottle, and then adjust the valve until spraying the soft even activator water fog, and the spray gun needs to equip with the compressor together.

Function: Spray even activator on the water transfer printing film to dissolving the hydrographic film, then the ink design will expend on the water surface, you can dip the item through the film on water.

This is the dipping video: https://www.youtube.com/watch?v=lWYl-pjbPkE

2. Hydro Dipping Tank

As a key piece of equipment for hydro dipping, the hydro dipping tank plays an important role during the water transfer printing process, its functions can make hydro dipping easier.

Hydro dipping tank on the market must have these basic functions:

a. Heating function:

b. Washing System:

c. Water Recirculation:

Other functions:

3. Spray Booth

Water transfer printing can be used for almost any materials, but you need to apply the based paint on the surface before hydro dipping except ABS material.

Thus spray booth shows its importance during the hydro dipping process, it can absorb the painting fog and smell into the water, clean your painting environment, and I also suggest you wear a 3M master when painting, you will thanks me for this suggestion when you painting, hahaha…

4. Rinse Tank

The rinse tank is used for washing the dipped products in big quantity once.

Generally, the rinse tank has many water jet, spray cool fog water, or heat fog water to clean the small dipped products. The rinse tank has a square shape and tunnel shape on the market, you can choose the suitable one for yourself.

Of course, if your product is a big volume part, you can wash it by yourself.

5. Drying Equipment

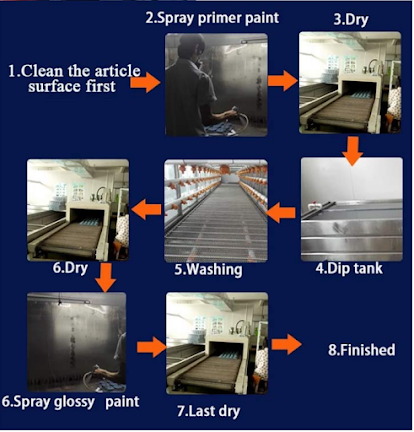

Hydro dipping drying equipment is used for drying out the dipped items, there are two steps of drying during the water transfer printing process as below:

From the steps of hydro dipping, you can see the drying steps are important for hydro dipping, especially for metal material such different to paint oil primer. The dipped effect will be better after painting, if possible, you can get one drying machine for your hydro dipping business.

Finally, the types of equipment for hydro dipping are: spray gun, compressor, hydro dip tank, spray booth, rinse tank and drying oven.

This comment has been removed by the author.

This comment has been removed by the author.

I think this is an educational post and it is exceptionally helpful and learned. hence, I might want to thank you for the endeavors you have made recorded as a hard copy this article. commercial cleaning services