How to Hydro Dipping Speedshape At Home?

Hydro dipping speed shape for showcase in your shop that is an important and basic thing for your hydro dipping business beginning. Therefore, how to hydro dipping speed shapes successfully is a necessary skill for you. I will show you how to hydro dip speed shapes at home in the following.

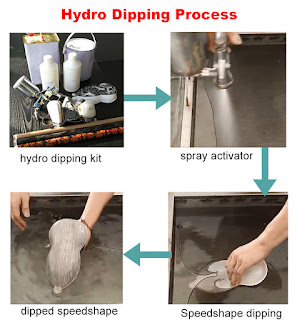

First Step: prepare basic hydro dip kit

You need to prepare hydrographic sheets, speedshape, activator B and spray gun or thick spray bottle.

Speed shapes

You need to choose the various shape of speed shapes according to your display plate and ABS price.

Of course, the material of speedshape needs to be ABS plastic, which is the only material that can be applied by hydrographic film directly no need to apply based painting.

Hydrographic film sheet

You can choose some typical hydrographic film sheets to dip, such as camo dipping film, military camouflage water transfer printing film sheet, popular skull dipping film sheet, classic wood grain transfer film, women’s follower hydro dip film sheet, kids’ popular cartoon hydrographic film sheet, dreamy digital or graffiti hydro dipped film sheet, etc.

To select 5 pcs per type or more according to your speed shape quantity and the space of your showcase bracket.

And cut more hydrographic film sheets for failure and testing.

Second Step: prepare water at a suitable temperature

To pour some water which temperature ranges from 28 degrees – 35 degrees into the tub or other containers you have at home.

You can add hot water into cold water to adjust the temperature of the water, or you also can put the container with water under the sunshine, heat the water by nature. It depends on yourself.

Third Step: Adjust the spray gun

Put the hydrographic film sheet on the water, spray the activator with a spray gun.

Try to spray activator B on the hydro dipping sheet evenly, and observe the change of dipped film, if it dissolves too fast and its design is changed, then you need to reduce the amount of spray, if the design is damaged after your spraying, you need to adjust the strength of spraying.

Anyway, try to test several times, you will get the suitable point for spray gun, practice makes perfect.

Fourth Step: Hydro dip the speed shape

As the first step does, you select many types of hydrographic dipping film sheets, and every type is different, their hydro dipping maybe has some differences too.

Camo design hydrographic film is the easiest to succeed when you don’t have enough dipping experience. And the wood grain hydrographic film design is easiest to get wrong during hydro dipping.

Thus, I suggest you begin to dip firstly from the camo hydrographic film sheet.

Fifth Step: Weed out the dipped dirty

After hydro dipping, you need to weed out the dirty on the water, to ensure clean water for the next hydro dipping, if it is too dirty, you can change the water that ranges from 28 degrees to 35 degrees.

Sixth Step: Washing the dirty on speed shape

There are some films dirty leave on the surface of speed shape, you need to wash dirty by water pipe, wash all dipped speed shapes together.

Seventh Step: Dry out dipped speed shapes

To place the dipped speed shape one by one on the bracket, dry out naturally.

Eighth Step: Supply gloss paint

Supply gloss paint on the surface of dipped speed shapes, to protect the design on surface, so that the design won’t be broken after being left for a long time.

Cheers! Those are all steps of how to hydro dip speed shape at home, you can do the hydro dipping showcase at home by yourself according to these steps.

Just do it. Hope you can do it successfully!