Hydro dipping is a unique

process of applying printed designs or graphics on product surfaces. It is also

known as hydro graphics, immersion printing, water transfer printing, water

transfer imaging, and hydro imaging.

Hydro dipping’s popularity

has skyrocketed to unimaginable heights over the years due to the amazing

benefits it offers. The following are the major factors accounting for the popularity of hydro dipping:

·

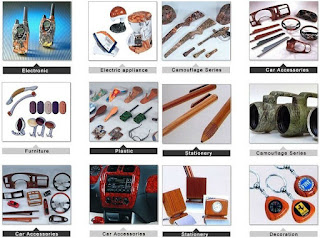

Hydro dipping is suitable for many

materials.

Hydro dipping can be

applied on almost any material you can think of. It can be used on metals,

plastics, ceramics, hard woods, glass and many other materials.

Every material needs to match with a suitable oil primer, then dry out, do hydro dipping.

·

Hydro dipping has a wide range of industry

applications.

Hydro dripping has many

applications in several industries. The most popular industry is the automotive

industry. It can be used for motorcycle plastics, interior and exterior car

parts, dashboards and rims.

·

Hydro dipping is cheap

Hydro dripping is

affordable when compared to traditional painting.

The painting always needs more cost for customized or big production from the factory. But hydro dipping can be operated at home, you can do DIY hydro dipping for your phone case, laptop shell, fans even for the plastic desk.

· The hydro dipping has unlimited designs

There are unlimited design

options in hydro dipping. We always can see the new pattern in the hydrographic film market, there are specialized designers to design the pattern for the hydrographic films’ production.

If you can’t find the pattern on the market, or you want to have a design by yourself.

Customized hydro dipping pattern

Then there is a good news, we can order some blank hydrographic film from the water transfer printing film supplier, and activator A, print our design on the blank film by inkjet printer, and then supply activator A on the blank film to protect ink, so that this printed blank hydrographic film can do hydro dipping like normal hydrographic film.

So, we can say hydro dipping can dip any image on the items.

Almost any design can be applied on an item or a

product through hydro dipping. Highly spectacular designs can be produced

through hydro dipping.

·

Hydro dipping product is durable.

If you supply gloss primer on the hydro dip items to protect the design on the product. Hydro dripping designed

items are durable and long-lasting, can keep the design in clear effect.a long time.

·

Hydro dipping can be used for both single

and large volume production designs.

Hydro dipping can be used

to design a single item. It can also be used to design large volumes of

products. This makes it suitable for both individual and industrial

purposes.